How did the Technical Institute of Military Vehicles evaluate SuperTech®?

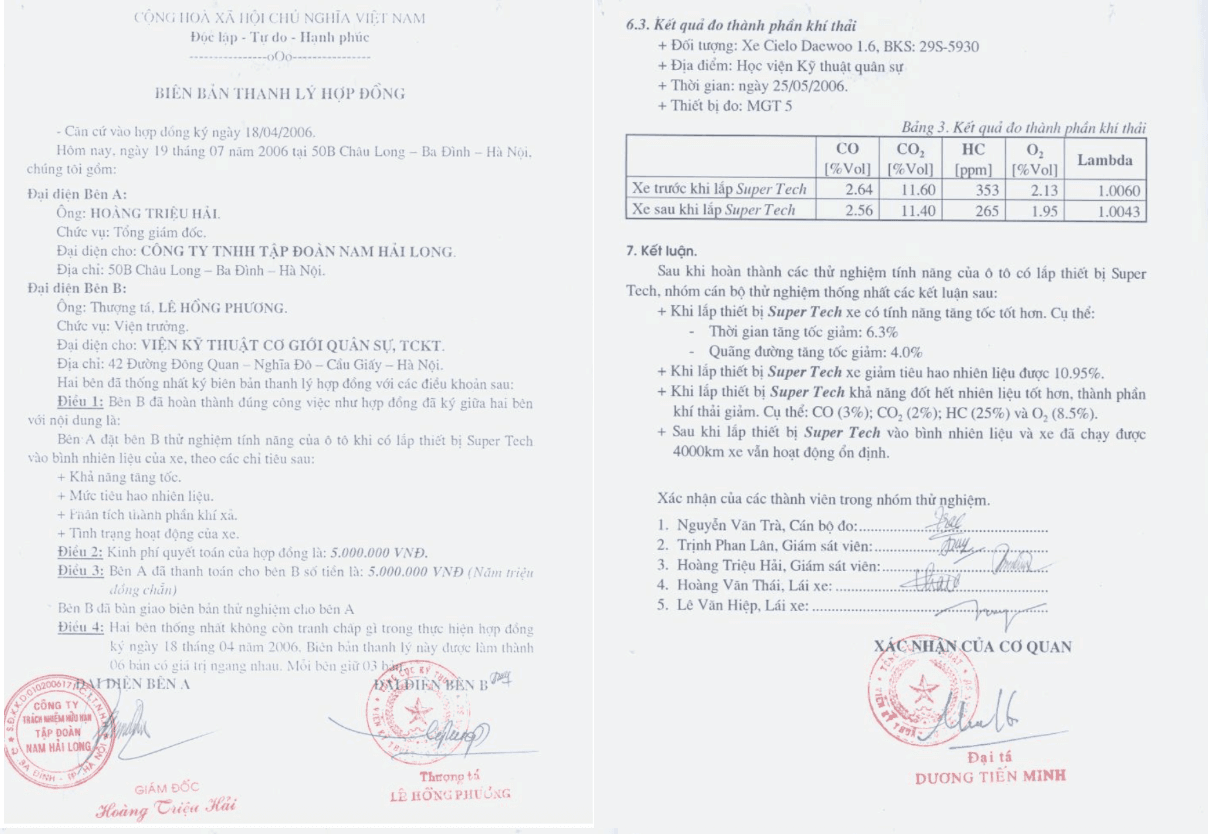

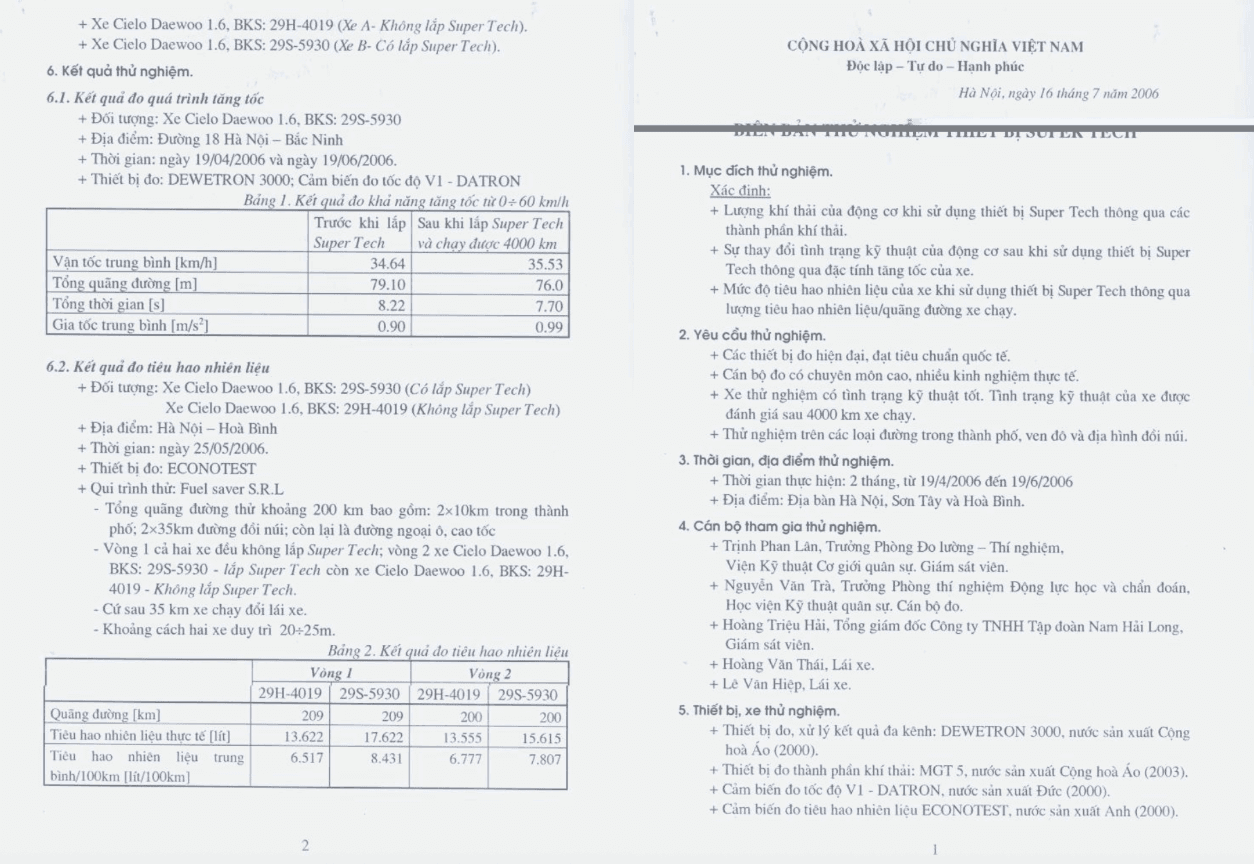

To assess the impact of upstream combustion optimization on fuel consumption, exhaust emissions, and vehicle performance, the Technical Institute of Military Vehicles, operating under the Vietnamese Ministry of Defence, conducted a structured real-world evaluation of the SuperTech® Combustion Optimizer.

The evaluation was carried out by Institute engineers over an extended testing period and was designed to measure performance changes under representative operating conditions without modifying engine hardware or control systems.

Evaluation Scope & Method

The testing program included:

On-road fuel consumption testing over approximately 200 km, incorporating:

Urban driving

Highway operation

Mountain terrain

Comparative testing using:

One vehicle equipped with SuperTech®

One identical control vehicle without SuperTech®

Driver rotation and controlled spacing between vehicles to minimize operational bias

Exhaust gas measurements conducted at the Institute using certified measurement equipment

Vehicle performance testing, including acceleration measurements

All tests were conducted using the same vehicles, routes, and measurement procedures before and after installation. No engine modifications, tuning, or changes to vehicle systems were made during the evaluation period.

Which equipment and standards were used to validate the results?

Testing and data acquisition were conducted using internationally recognized instrumentation, including:

DEWETRON 3000 data acquisition system (Austria)

MGT5 exhaust gas analyzer (Austria)

DATron V1 optical speed sensor (Germany)

ECONOTEST fuel-consumption measurement system (United Kingdom)

The Institute confirmed that all equipment met applicable international technical standards and that testing was performed under expert supervision.

What were the observed results following installation?

Based on comparative testing and measured data, the Institute documented:

Fuel consumption reduction of approximately 10.95%

Reductions in measured exhaust emissions, including:

Carbon monoxide (CO)

Carbon dioxide (CO₂)

Unburned hydrocarbons (HC)

Improved acceleration performance, including reduced time and distance required to reach target speeds

Following extended operation of approximately 4,000 km, the Institute reported that the engine continued to operate in stable and good condition, with no adverse effects observed.

What is the key takeaway for engineers and fleet operators?

The Technical Institute of Military Vehicles evaluation demonstrates that non-invasive, in-tank combustion support technologies can be independently assessed under real-world operating conditions using certified measurement systems.

The documented results show measurable improvements in fuel efficiency, combustion behavior, and exhaust characteristics without modifying engine hardware, ECU calibration, or emissions control systems.

This reference documents observed outcomes under specific test conditions and does not constitute a regulatory certification or guarantee of results. Performance may vary depending on vehicle condition, operating environment, fuel quality, and duty cycle.