How did LACTEC (Brazil) evaluate SuperTech®?

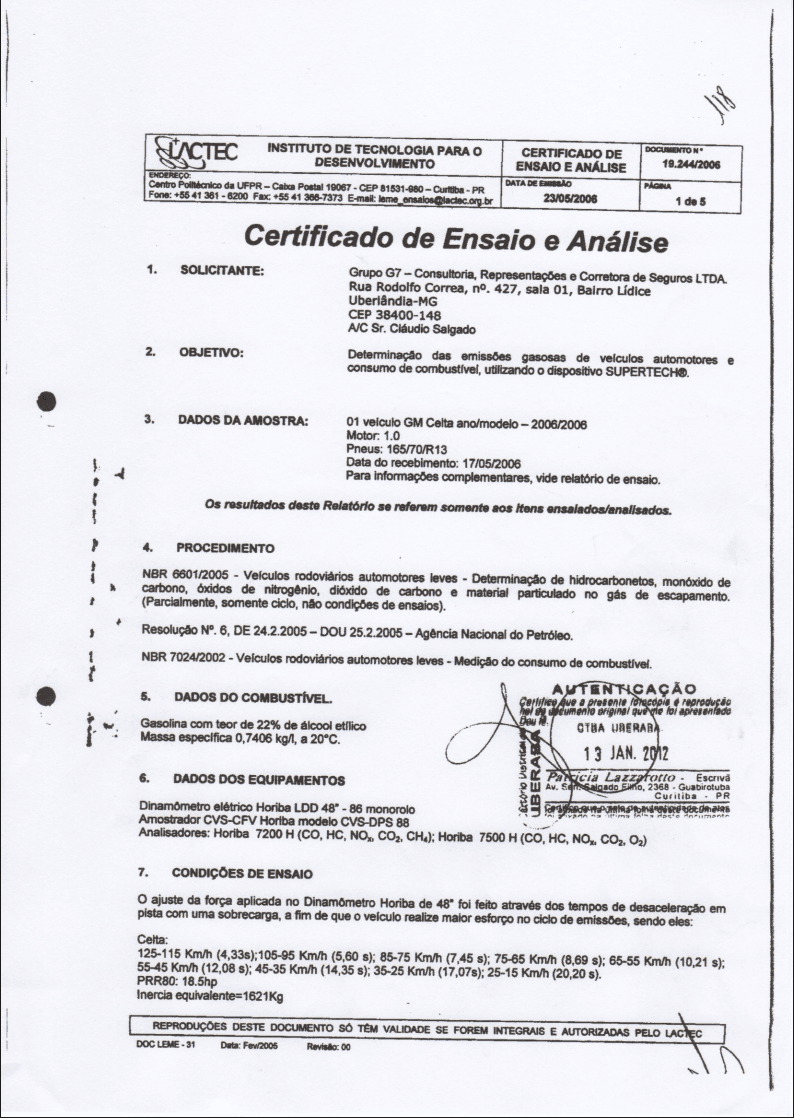

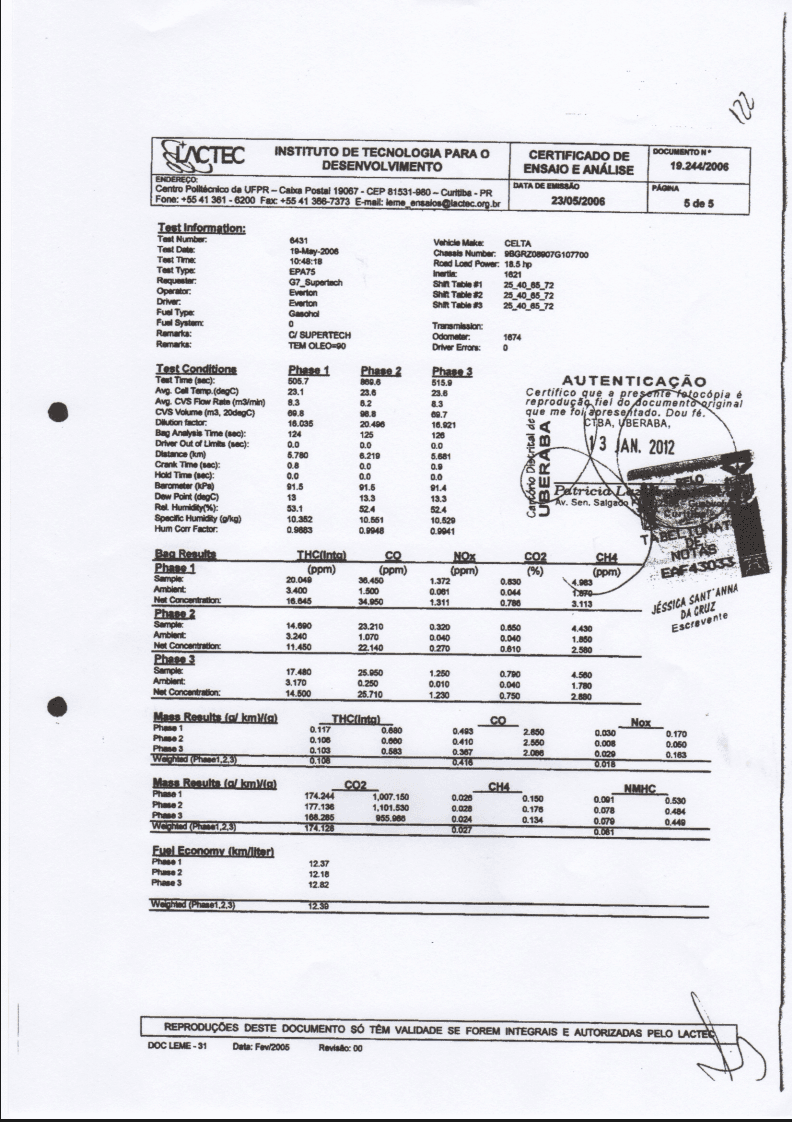

To assess the impact of upstream combustion optimization on fuel consumption and exhaust emissions, LACTEC – Instituto de Tecnologia para o Desenvolvimento (Brazil) conducted a certified laboratory evaluation of the SuperTech® device.

The testing was performed by LACTEC’s accredited vehicle emissions laboratory, using standardized procedures to measure regulated exhaust gases and fuel consumption under controlled dynamometer conditions.

Evaluation Scope & Method

The evaluation focused on:

Determination of gaseous emissions from light-duty vehicles, including:

Hydrocarbons (HC)

Carbon monoxide (CO)

Nitrogen oxides (NOx)

Carbon dioxide (CO₂)

Methane (CH₄)

Measurement of fuel consumption

Comparative testing conducted with SuperTech® installed

Testing carried out under a Brazilian FTP-75 driving cycle, simulating urban vehicle operation

The tested vehicle was a GM Celta (model year 2006), evaluated under controlled laboratory conditions. No engine modifications, tuning, or changes to vehicle systems were made during the evaluation.

Which standards and equipment were used to validate the results?

Testing was conducted in accordance with recognized Brazilian and international standards, including:

NBR 6601/2005 – Determination of exhaust emissions from light-duty vehicles

NBR 7024/2002 – Measurement of fuel consumption

ANP Resolution No. 6/2005 – National Petroleum Agency procedures

Laboratory instrumentation included:

Horiba chassis dynamometer (48” rollers)

Horiba 7200 and Horiba 7500 exhaust gas analyzers

Certified fuel-consumption measurement systems

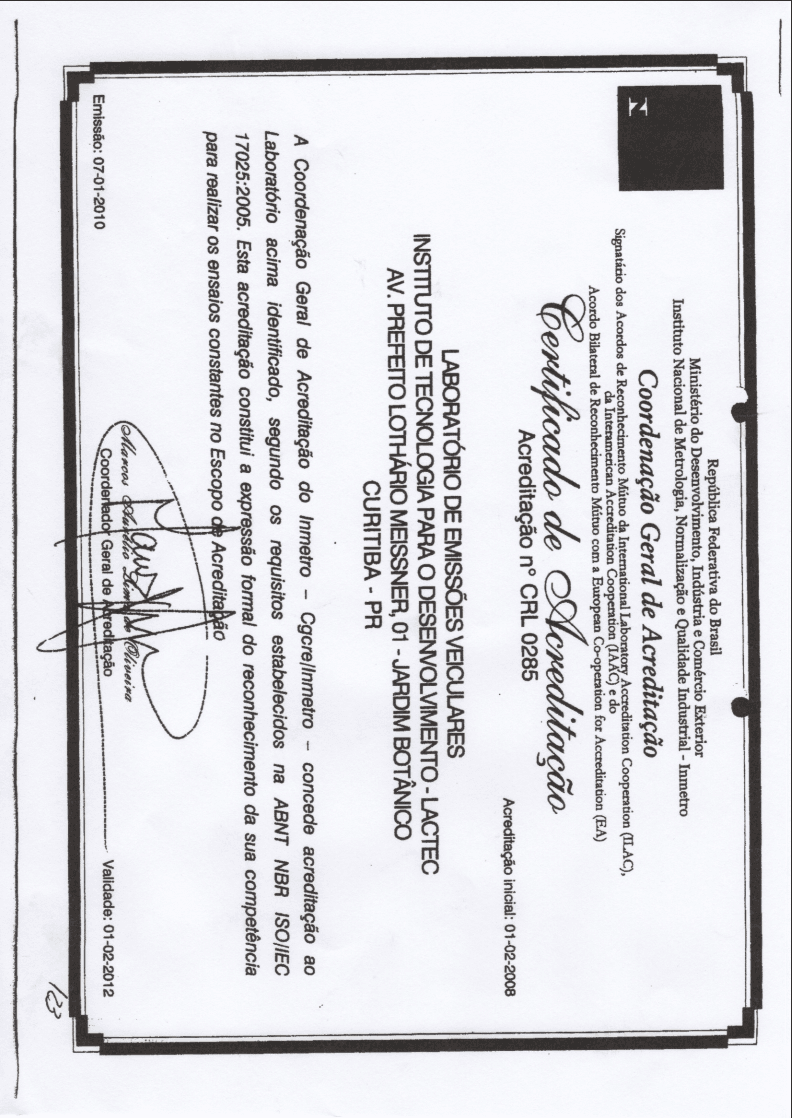

The LACTEC emissions laboratory is formally accredited by INMETRO under ABNT NBR ISO/IEC 17025, confirming technical competence and measurement validity.

What were the observed results following installation?

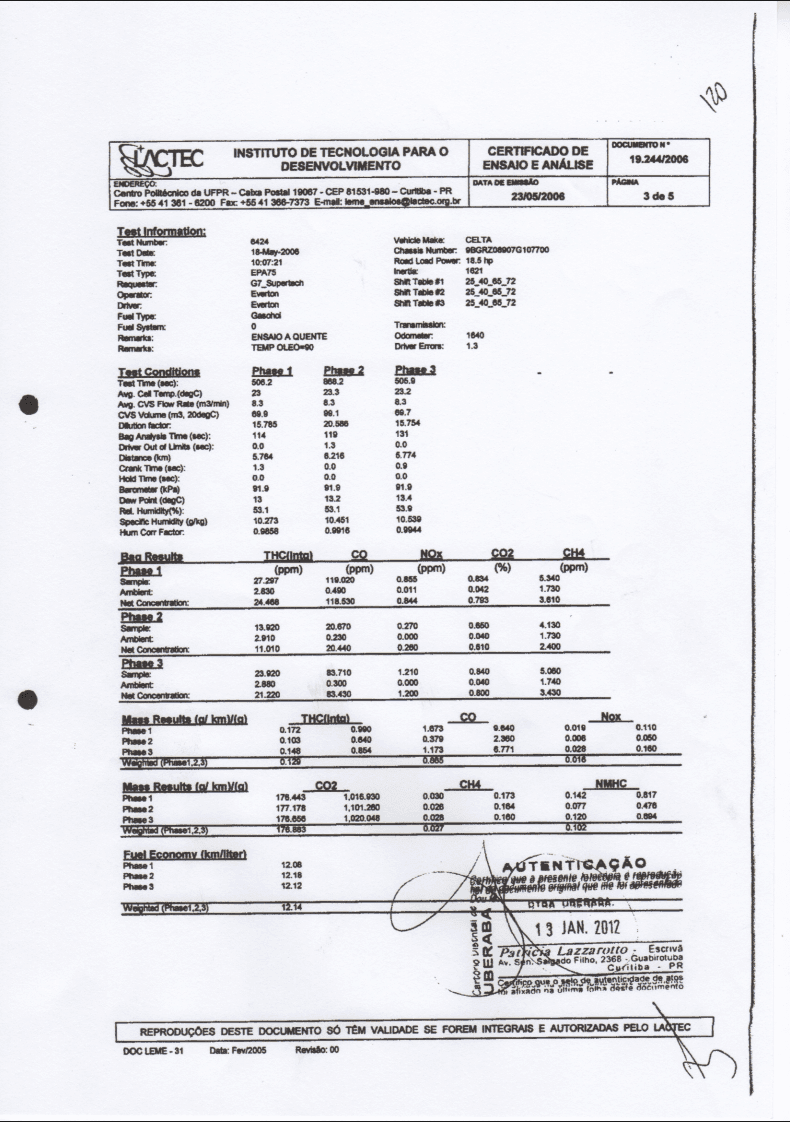

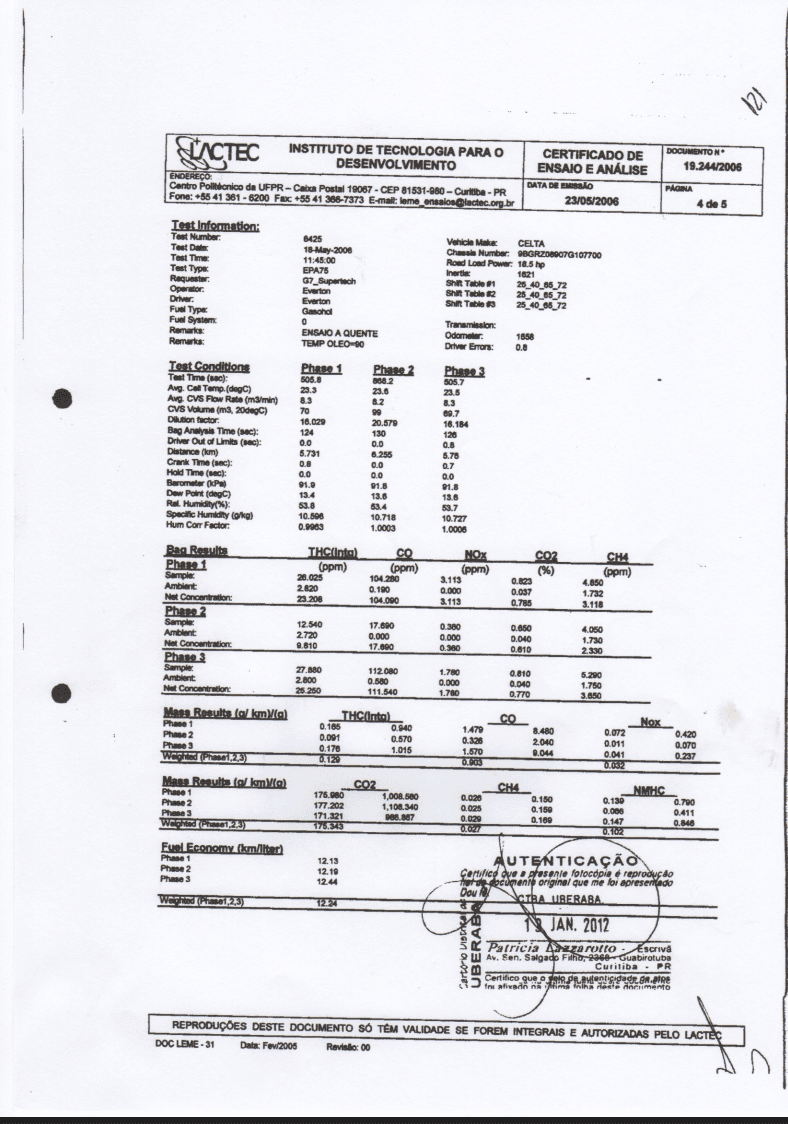

Based on certified laboratory measurements, the LACTEC evaluation documented:

Improved fuel economy, measured across multiple test phases of the FTP-75 cycle

Reductions in measured exhaust pollutants, including:

Carbon monoxide (CO)

Unburned hydrocarbons (HC)

Stable and compliant NOx levels throughout the test cycle

Consistent exhaust gas behavior across repeated test phases

Results varied by test phase, which is typical for standardized emissions and fuel-consumption testing.

What is the key takeaway for engineers and fleet operators?

The LACTEC evaluation demonstrates that accredited laboratory testing can independently document measurable changes in fuel consumption and exhaust emissions associated with upstream, in-tank combustion support technologies.

This reference documents observed outcomes under certified laboratory conditions and does not constitute a regulatory certification or guarantee of results. Performance may vary depending on vehicle configuration, operating conditions, fuel quality, and duty cycle.