University Bench Testing Documents CO Reductions up to 70% with Fuel Savings of ~5–10%

How did Helwan University evaluate SuperTech®?

The Faculty of Engineering at Helwan University (Cairo, Egypt) conducted a laboratory-based evaluation to assess the impact of upstream fuel optimization on exhaust emissions and fuel consumption in petrol engines.

The testing was performed by the Automotive Engineering Department, using controlled bench and dynamometer methods to isolate changes in combustion behavior following the installation of SuperTech® inside the vehicle fuel tank.

Evaluation Scope & Method

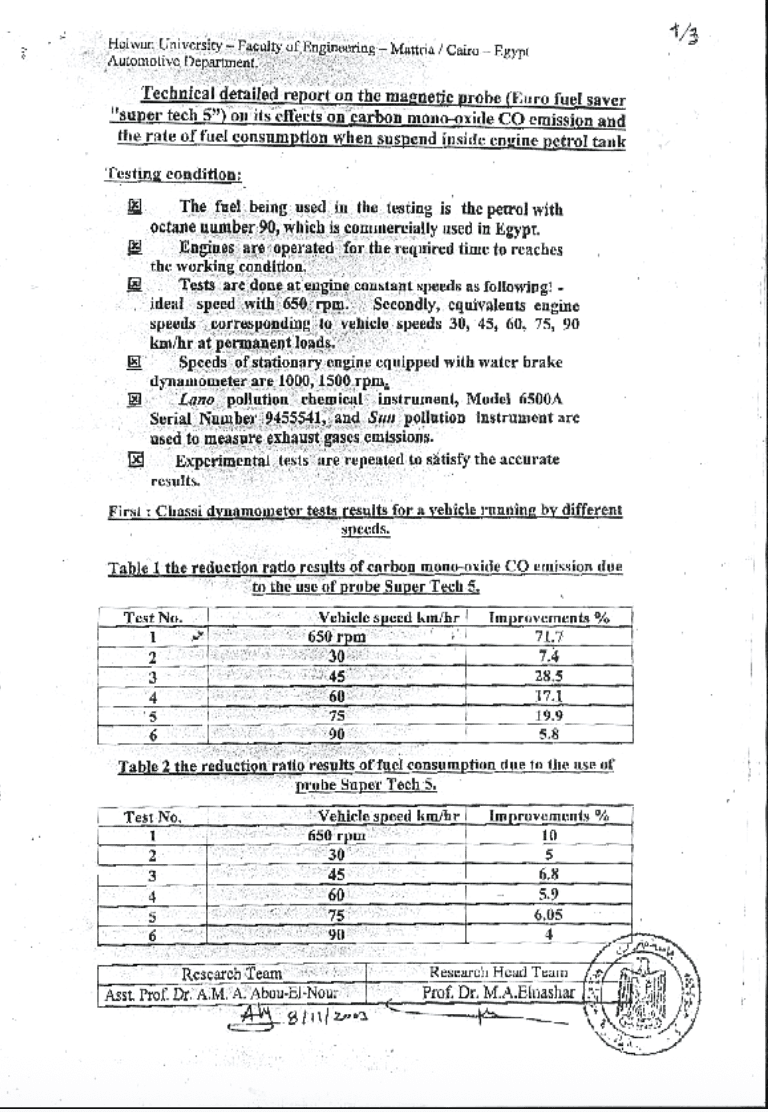

The evaluation consisted of controlled laboratory testing under repeatable operating conditions, including:

Petrol engines operated at constant engine speeds and loads

Bench and chassis dynamometer testing

Measurement of:

Carbon monoxide (CO) emissions

Fuel consumption

Tests conducted at multiple operating speeds to assess behavior across load ranges

Repeated measurements to verify consistency and accuracy

No engine modifications, tuning, additives, or changes to vehicle systems were introduced during testing.

What were the observed results following installation?

According to the laboratory test results documented by Helwan University:

Exhaust Emissions

Carbon monoxide (CO) reductions of up to ~70% were observed at lower engine loads

CO reduction trends remained measurable across increasing engine speeds, with decreasing magnitude at higher loads — consistent with combustion dynamics

Fuel Consumption

Fuel consumption reductions of approximately 5–10% were documented, depending on operating speed and test condition

The largest reductions were observed under low-speed and urban-style operating conditions, where combustion efficiency has a greater influence on fuel burn

What is the key takeaway for engineers and fleet operators?

The Helwan University evaluation demonstrates that laboratory bench testing can document measurable reductions in carbon monoxide emissions alongside moderate fuel-consumption improvements when upstream, in-tank fuel-conditioning technologies are applied.

This reference reflects controlled laboratory conditions and does not constitute a regulatory certification or guarantee of results. Performance may vary depending on engine design, vehicle condition, fuel quality, and operating duty cycle.