How did the National Autonomous University of Mexico (UNAM) evaluate SuperTech®?

To assess the impact of upstream combustion optimization on both fuel efficiency and exhaust emissions, the Laboratory of Emission Control (LCE) at the Faculty of Engineering, UNAM conducted controlled laboratory evaluations of the SuperTech® Combustion Optimizer.

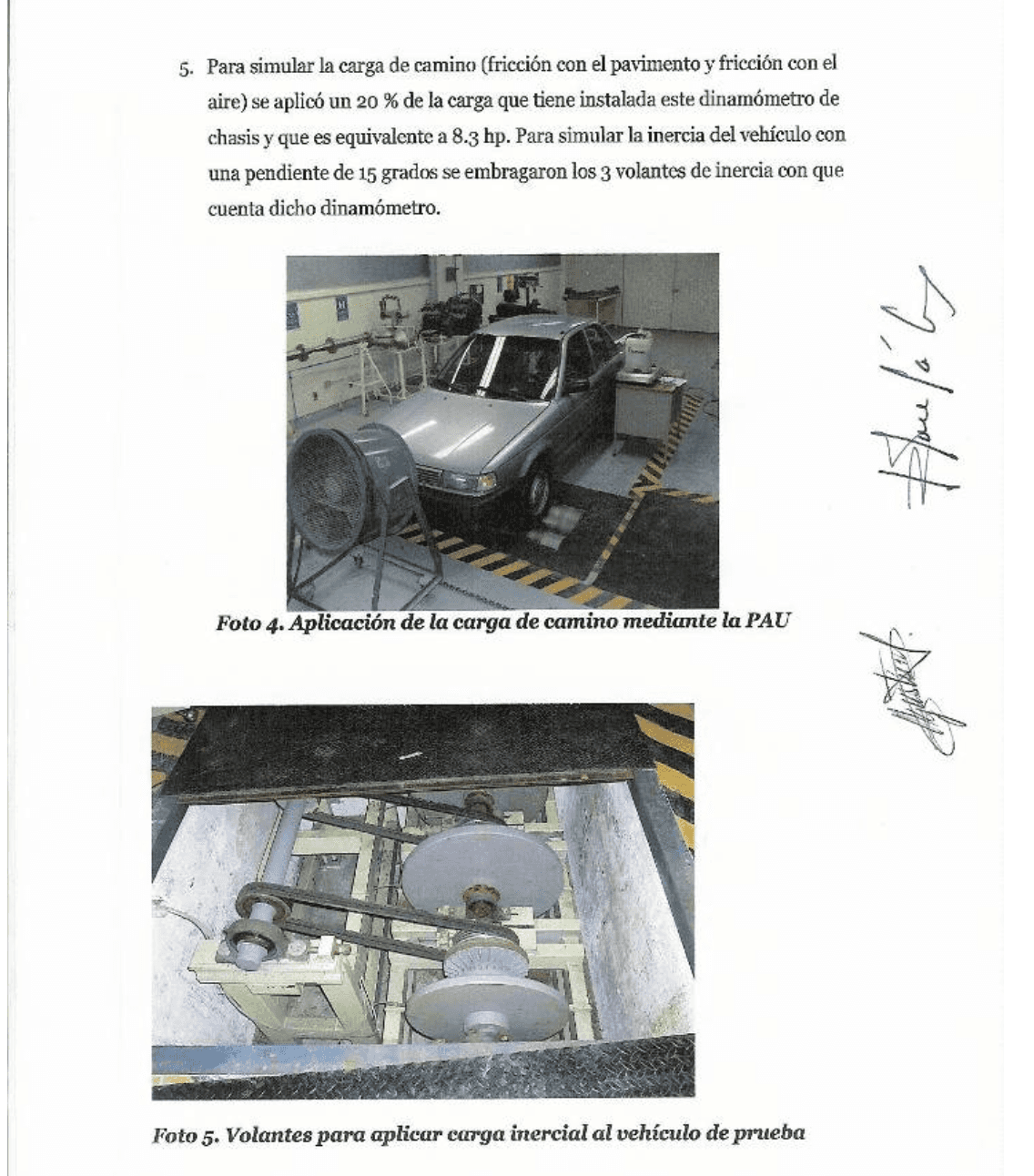

The evaluations were designed and executed by UNAM personnel using instrumented dynamometer testing, allowing repeatable measurement of fuel consumption, combustion performance, and regulated exhaust gases under simulated real-world driving conditions.

Evaluation Scope & Methodology

The testing program included:

Chassis dynamometer testing using a standardized urban driving cycle representative of the Mexico City metropolitan area

Controlled simulation of vehicle load, inertia, road resistance, and airflow

Measurement of fuel mass and volume consumption using calibrated digital scales

Continuous monitoring of exhaust gases, including:

Carbon monoxide (CO)

Carbon dioxide (CO₂)

Unburned hydrocarbons (HC)

Nitrogen oxides (NOx)

Oxygen (O₂)

Baseline testing without SuperTech, followed by repeated tests with SuperTech installed inside the fuel tank

All tests were repeated multiple times to confirm consistency and minimize measurement dispersion.

What were the observed results?

Fuel Consumption & Performance

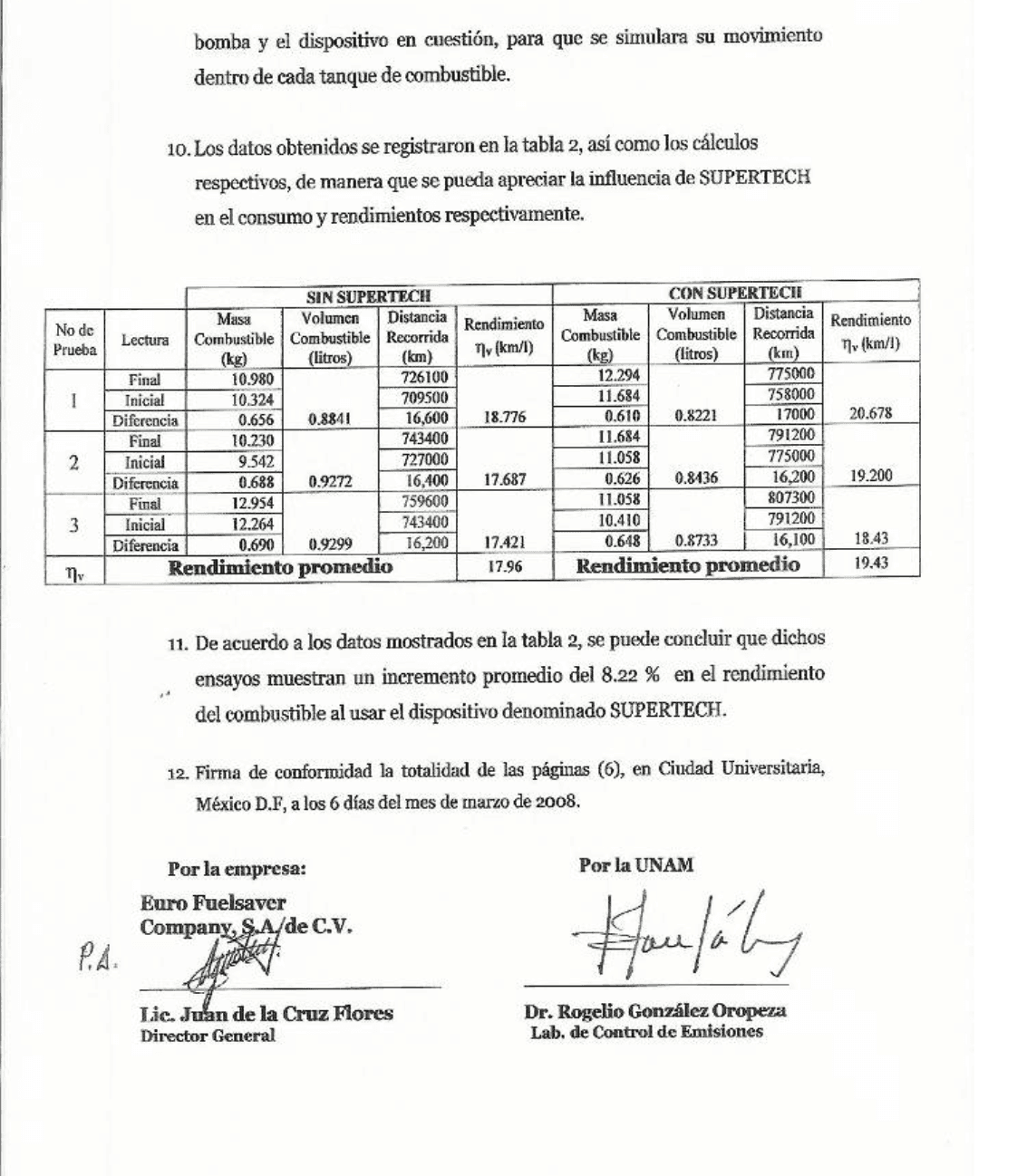

Across repeated dynamometer runs, the UNAM laboratory documented fuel-efficiency improvements ranging from approximately 8% on average to peak values of up to ~15% under specific test conditions when SuperTech was installed, compared to baseline operation without the device.

Exhaust Emissions Behavior

The emissions-focused evaluation recorded:

Stabilization of CO₂ concentrations, indicating more homogeneous combustion

Reductions in unburned hydrocarbons (HC) across the driving cycle

Lower and more stable CO concentrations

Marginal reductions in NOx, remaining well below applicable regulatory thresholds

Improved stability of oxygen concentration in exhaust gases, suggesting more complete oxidation of partially burned fuel components

Observed values were consistently within — and in several cases improved relative to — applicable Mexican emissions standards.

What is the key takeaway?

The UNAM evaluations demonstrate that non-invasive, in-tank combustion support technologies can be independently assessed under laboratory conditions using standardized measurement equipment.

The results show that upstream fuel conditioning may contribute to:

Measurable reductions in fuel consumption

More stable combustion behavior

Improved exhaust gas characteristics

— all without modifying engine hardware, ECU calibration, or emissions control systems.

These findings are documented observations from controlled testing and do not constitute a regulatory certification or guarantee of results. Performance may vary depending on vehicle type, condition, fuel quality, and duty cycle.