How did Cementos ARGOS evaluate SuperTech® in mining operations?

To assess the impact of upstream fuel optimization on fuel consumption in heavy mining vehicles, Cementos ARGOS (Colombia) conducted a structured field evaluation of SuperTech® on haul trucks operating at the Santana–Membrillal mining site.

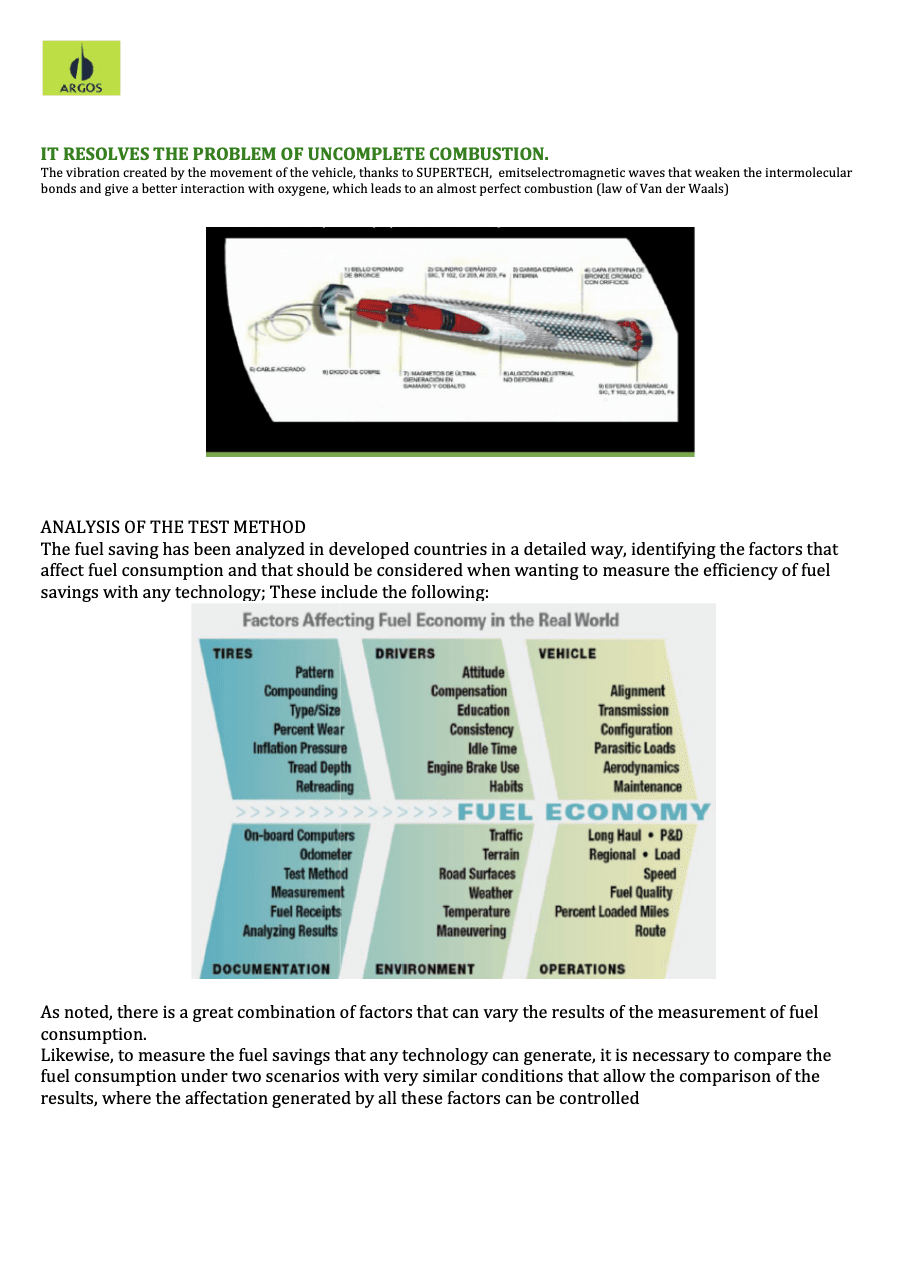

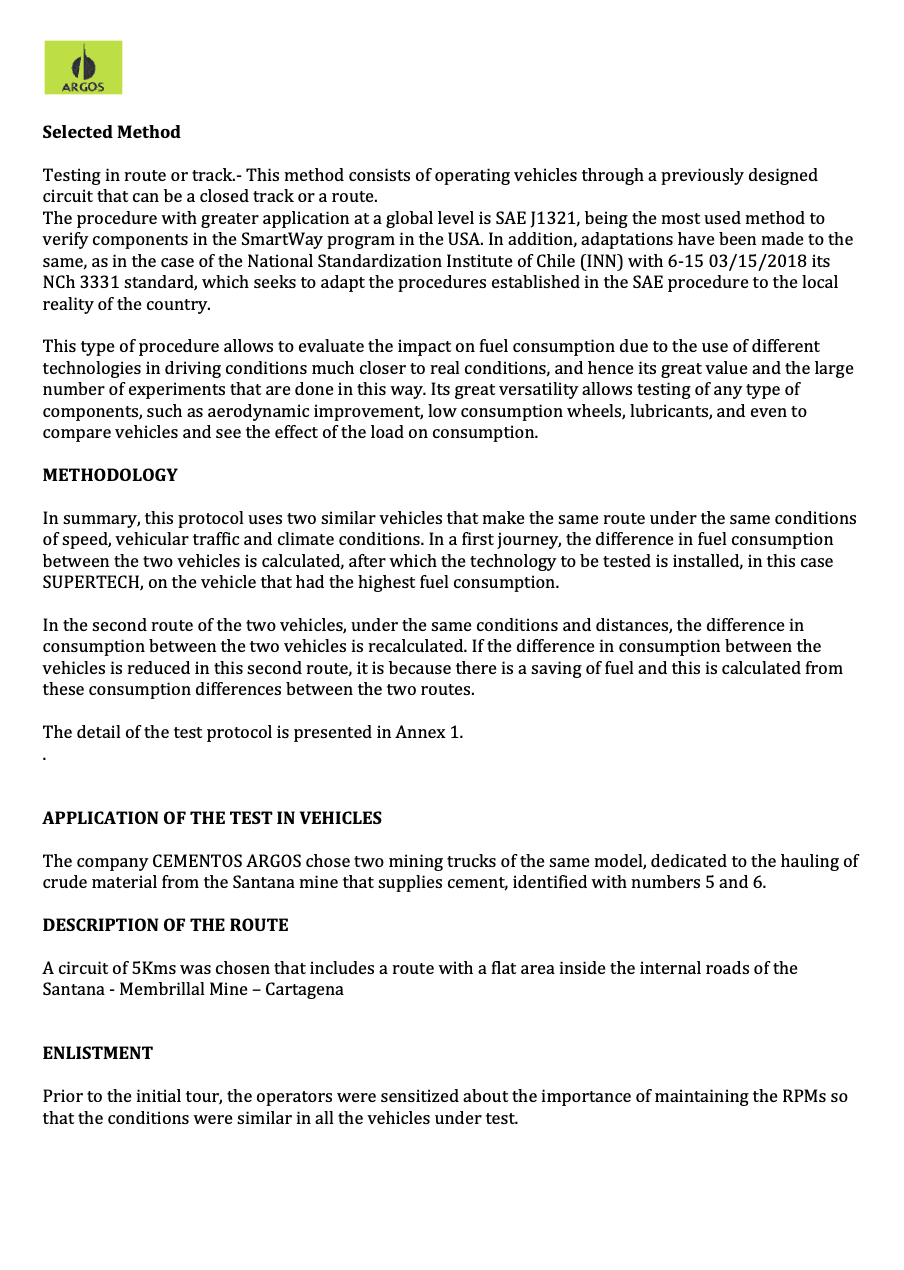

The evaluation was designed to measure fuel-consumption differences under real operating conditions, using a comparative methodology aligned with SAE J1321 principles, and was carried out on identical vehicles performing the same hauling duties.

Evaluation Scope & Method

The field evaluation included:

Two identical mining haul trucks dedicated to raw-material transport within the mine

A defined 5 km closed circuit inside the mining operation

Baseline testing without SuperTech®, followed by repeat testing with SuperTech® installed

Vehicles operated under:

Identical loads

Controlled engine RPM ranges

Driver rotation to minimize operator bias

Fuel consumption measured using external fuel tanks, weighed before and after each test run to determine net fuel use in kilograms

Multiple repeated runs to reduce measurement variability and stabilize averages

No engine modifications, tuning, or changes to vehicle systems were made during the evaluation.

Which standards and procedures were used?

The test methodology followed the principles of the SAE J1321 fuel-consumption test protocol, widely used internationally for evaluating fuel-saving technologies under real-world conditions.

The protocol included:

Control and test vehicles operated on the same route

Before-and-after comparison

Driver exchange between vehicles

Controlled environmental and operational parameters

This approach is designed to isolate fuel-consumption differences attributable to the tested technology.

What were the observed results following installation?

Based on documented measurements:

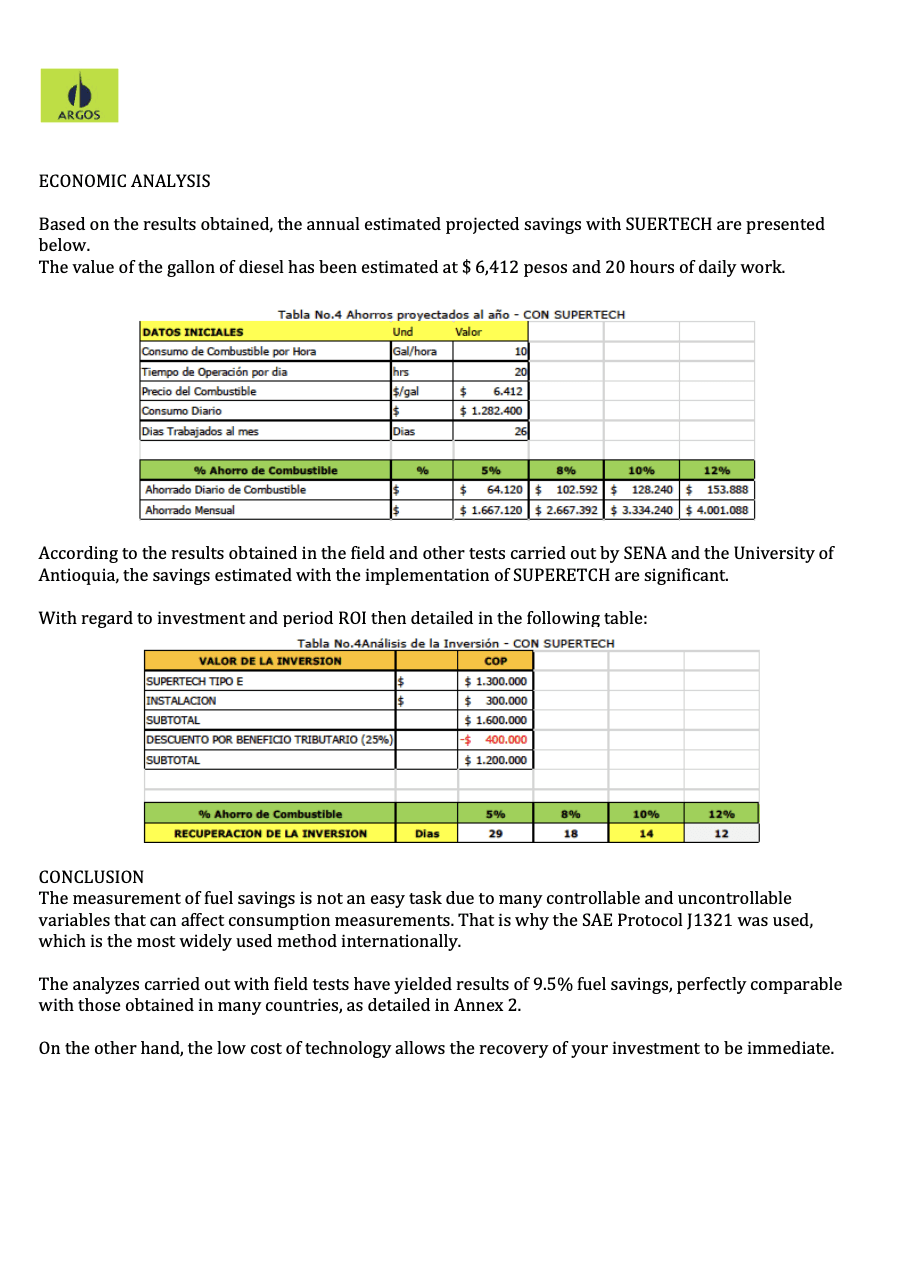

Baseline fuel-consumption difference between vehicles:

0.990 kg of fuel

Post-installation difference with SuperTech® installed:

Reduced to 0.050 kg of fuel

This corresponds to a measured fuel-consumption reduction of approximately 9.4–9.5%, attributable to the installation of SuperTech® under the tested conditions

The results were repeatable across multiple runs and were documented in the final test report.

What is the key takeaway for mining and heavy-industry operators?

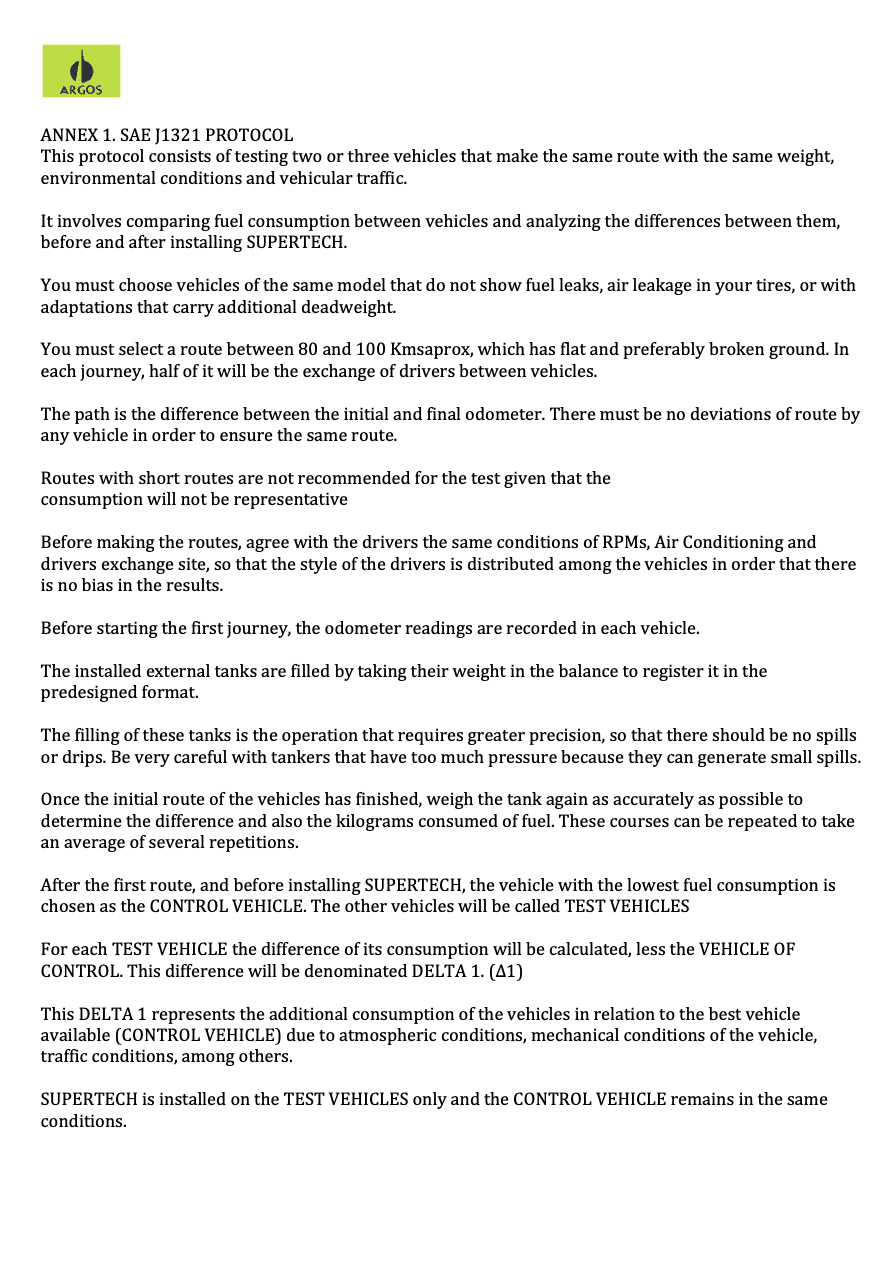

The Cementos ARGOS evaluation demonstrates that real-world, route-based testing using recognized comparative protocols can document meaningful fuel-consumption reductions in heavy mining vehicles.

This reference documents observed outcomes under specific operating conditions and does not constitute a regulatory certification or guarantee of results. Performance may vary depending on vehicle condition, load profile, fuel quality, and duty cycle.