How was SuperTech® evaluated on heavy construction equipment?

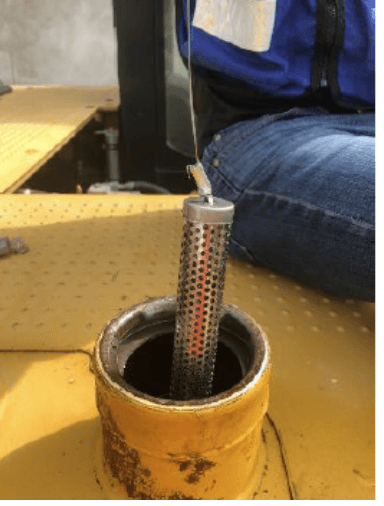

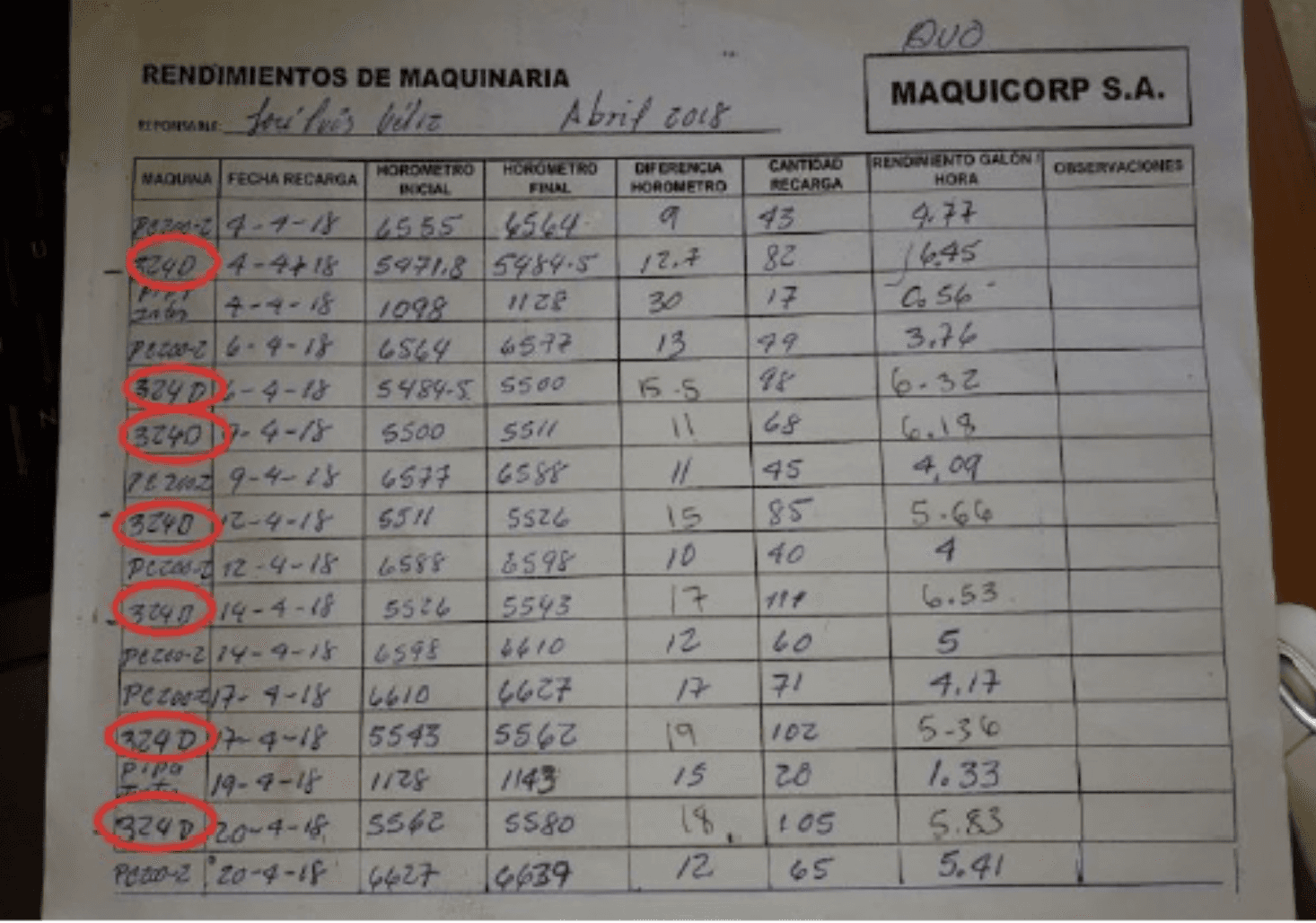

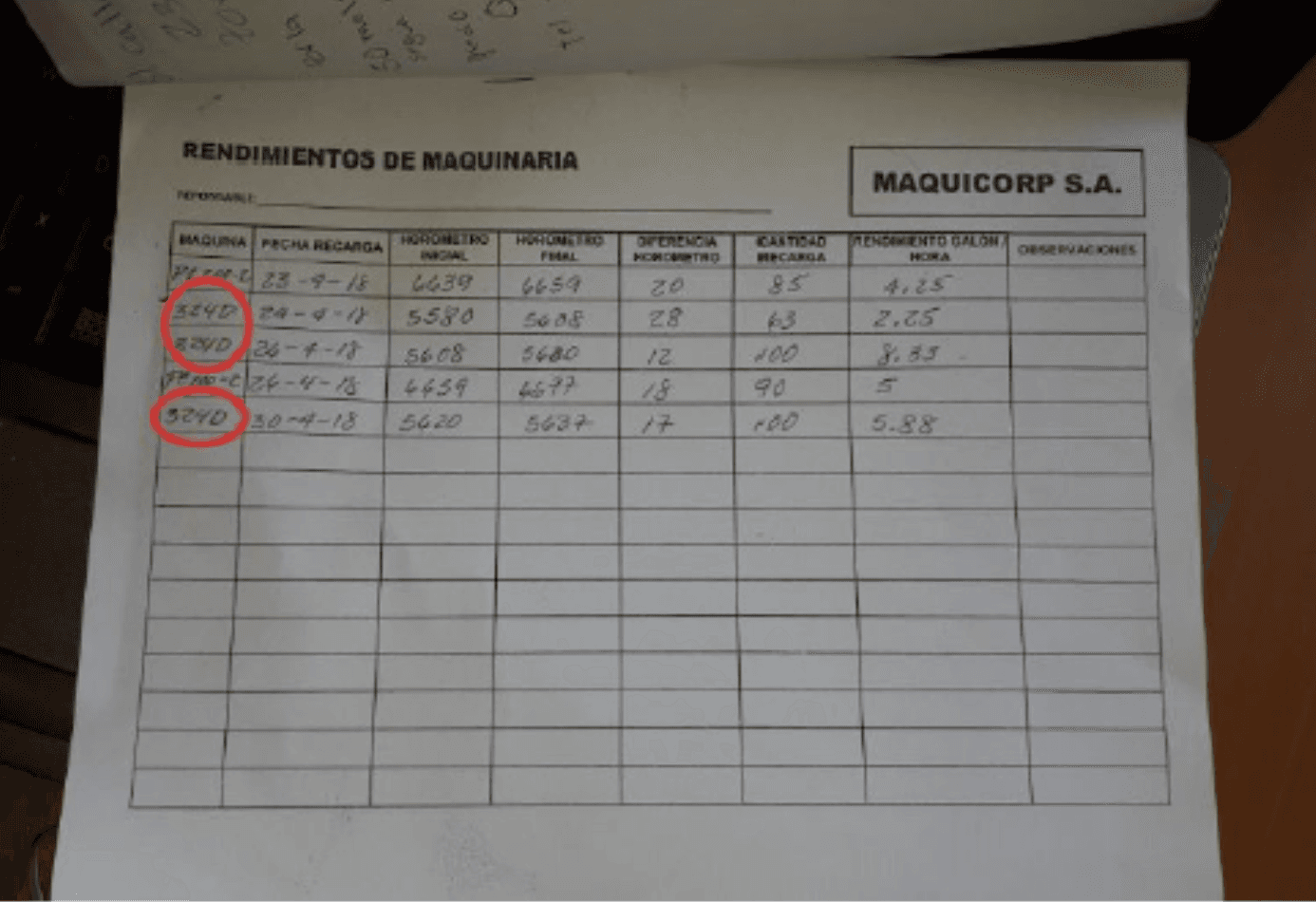

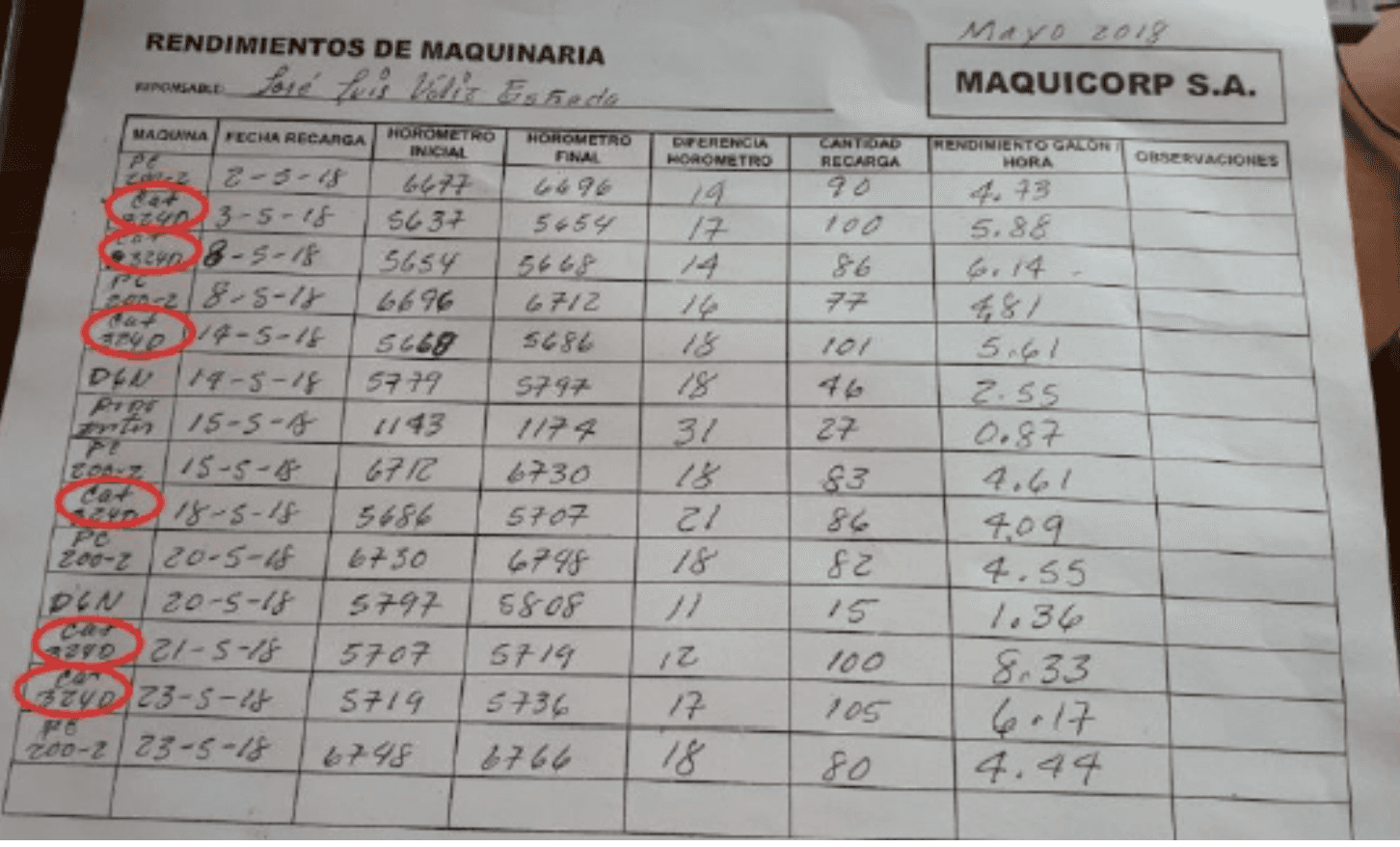

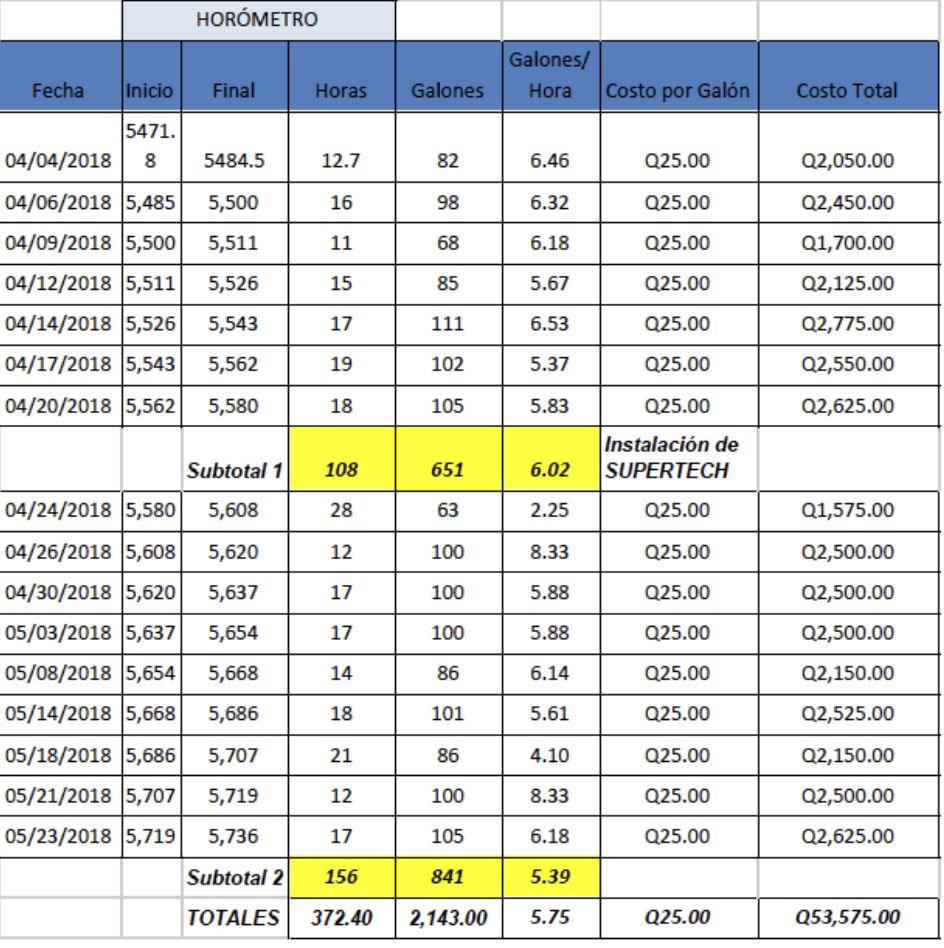

To assess the impact of upstream fuel optimization on fuel consumption in heavy construction equipment, a real-world field trial was conducted by Rosul Group during an active building excavation project in April–May 2018.

The evaluation focused on a Caterpillar CAT-324D excavator operating under normal job-site conditions, performing continuous cutting, loading, and material handling over full workdays.

Evaluation Scope & Method

The field trial included:

Test equipment: Caterpillar CAT-324D excavator

Operating schedule:

Daily operation from 7:00 a.m. to 5:00 p.m.

Single operator

Baseline period:

First 20 days of April 2018 without SuperTech®

Post-installation period:

April 20 to May 23, 2018 with SuperTech® installed

Fuel usage tracked using:

Hour-meter readings (horometer)

Fuel added to the tank every 2–3 days

Performance evaluated as gallons of fuel consumed per operating hour

No changes were made to the engine, operating procedures, or workload during the test period.

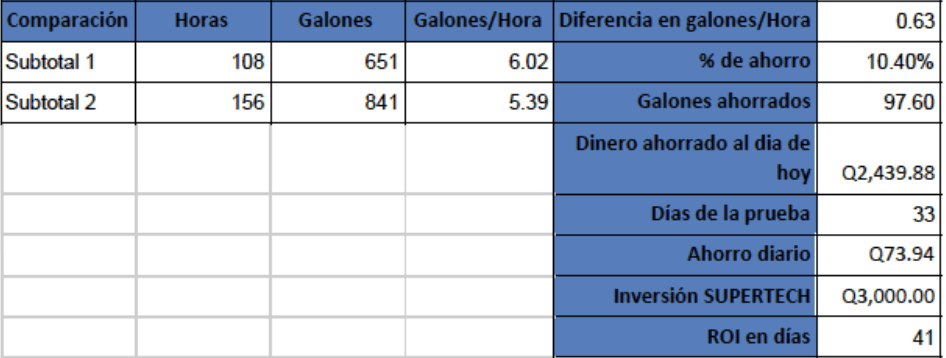

What were the observed results following installation?

Based on documented operating logs and fuel records, the evaluation showed:

Baseline fuel consumption:

6.02 gallons per hour (pre-installation)

Post-installation fuel consumption:

5.39 gallons per hour

Fuel reduction:

0.63 gallons per hour, representing a 10.40% reduction

Over the 33-day test period, this translated into:

97.6 gallons of fuel saved

A documented return on investment of approximately 41 days, based on local fuel pricing

The excavator continued to operate normally throughout the evaluation, with no reported operational issues.

Additional comparative observation

As a supplementary comparison, SuperTech® was also installed on one of two identical hydro-pressure washers used on the same project site. Operators reported a noticeable reduction in fuel usage compared to the untreated unit, with estimated daily fuel savings based on refueling frequency.

This additional observation was qualitative in nature and used as supporting context.

What is the key takeaway for operators and fleet managers?

This field trial demonstrates that real-world, source-level fuel optimization can produce measurable fuel-consumption reductions in heavy construction equipment operating under continuous load.

The results document observed outcomes under specific job-site conditions and do not constitute a regulatory certification or guarantee of results. Performance may vary depending on equipment condition, workload, fuel quality, and duty cycle.