How was SuperTech® evaluated on aggregate and mining equipment?

To evaluate the impact of upstream fuel optimization on fuel consumption across different machine classes, a structured field study was conducted by an aggregate and mining equipment manufacturer and distributor operating crushing, batching, and excavation machinery.

The evaluation assessed SuperTech® across three different equipment categories, representing petrol and diesel engines with fuel-tank capacities ranging from 55 to over 500 liters, under normal operating conditions.

Evaluation Scope & Method

The study included testing of three SuperTech® models:

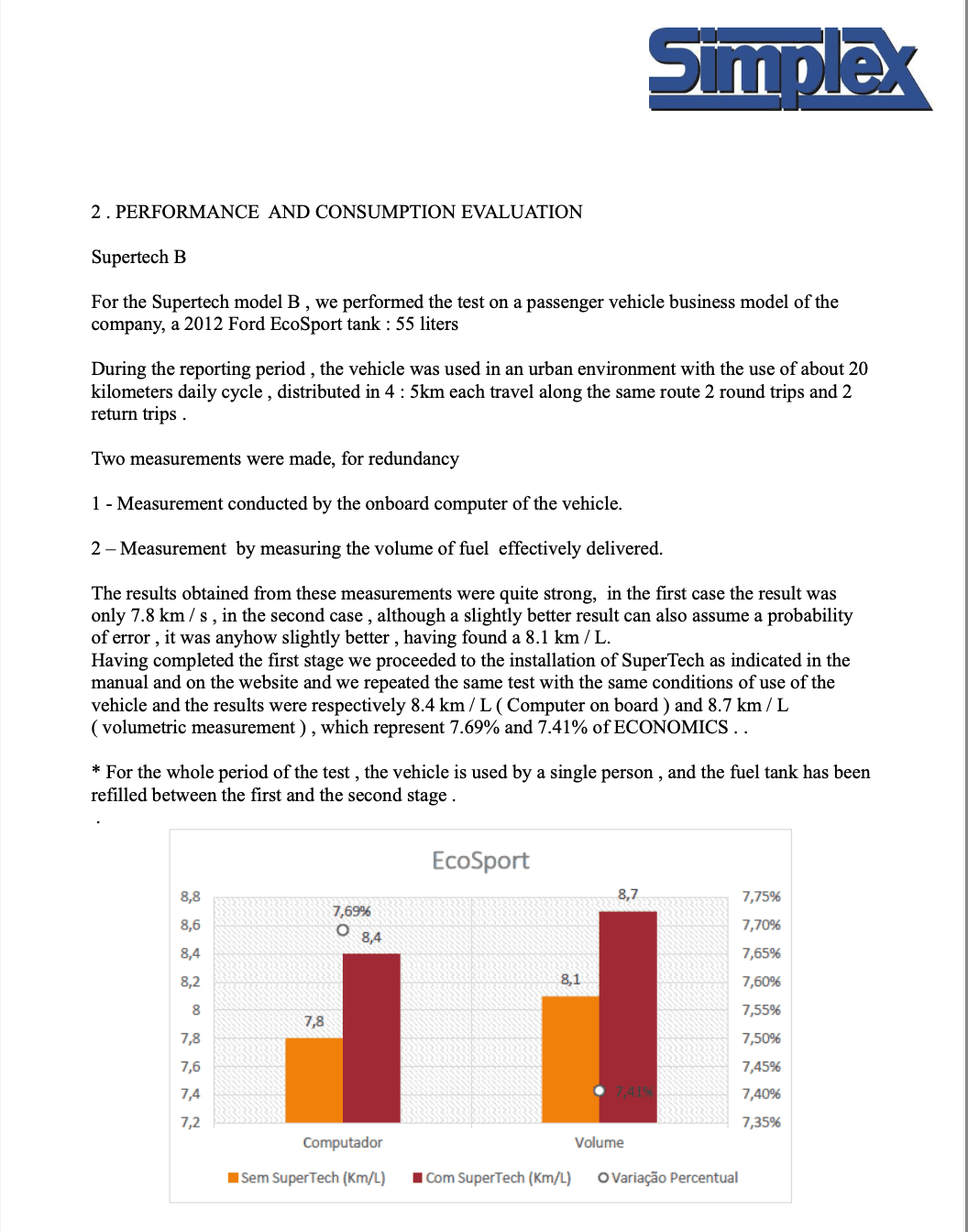

SuperTech® Model B (Passenger Vehicle – Petrol)

Vehicle: 2012 Ford EcoSport

Fuel: 87-octane petrol (E25)

Operating cycle:

Urban driving, ~20 km/day

Repeated identical routes

Test duration:

5 days baseline (no SuperTech®)

5 days post-installation

Measurement methods:

Onboard computer

Volumetric fuel measurement

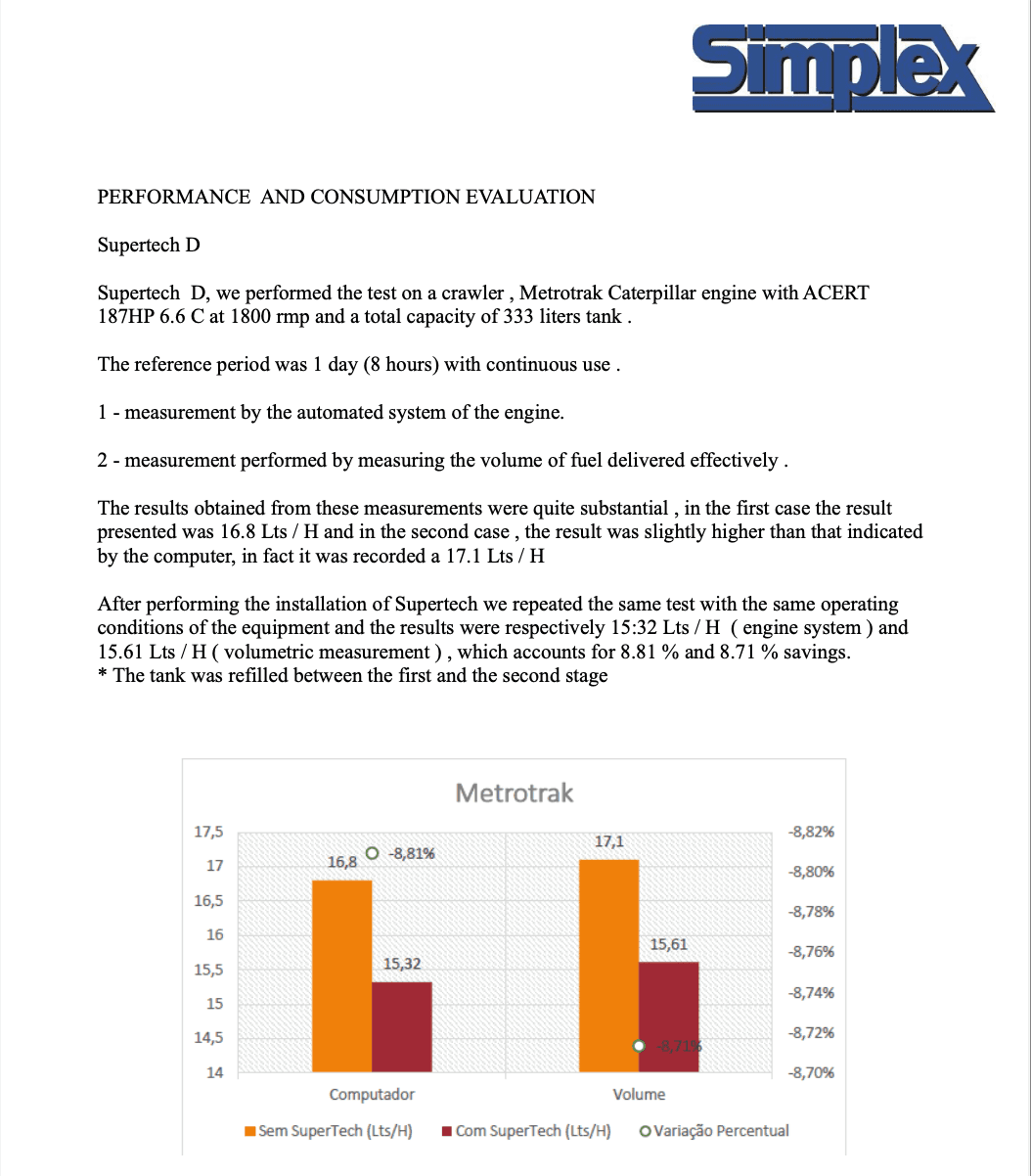

SuperTech® Model D (Crawler Crusher – Diesel)

Equipment: Metrotrak crawler with Caterpillar ACERT engine

Power: 187 HP

Tank capacity: ~333 liters

Test duration:

1 full workday baseline

1 full workday post-installation

Measurement methods:

Engine monitoring system

Volumetric fuel measurement

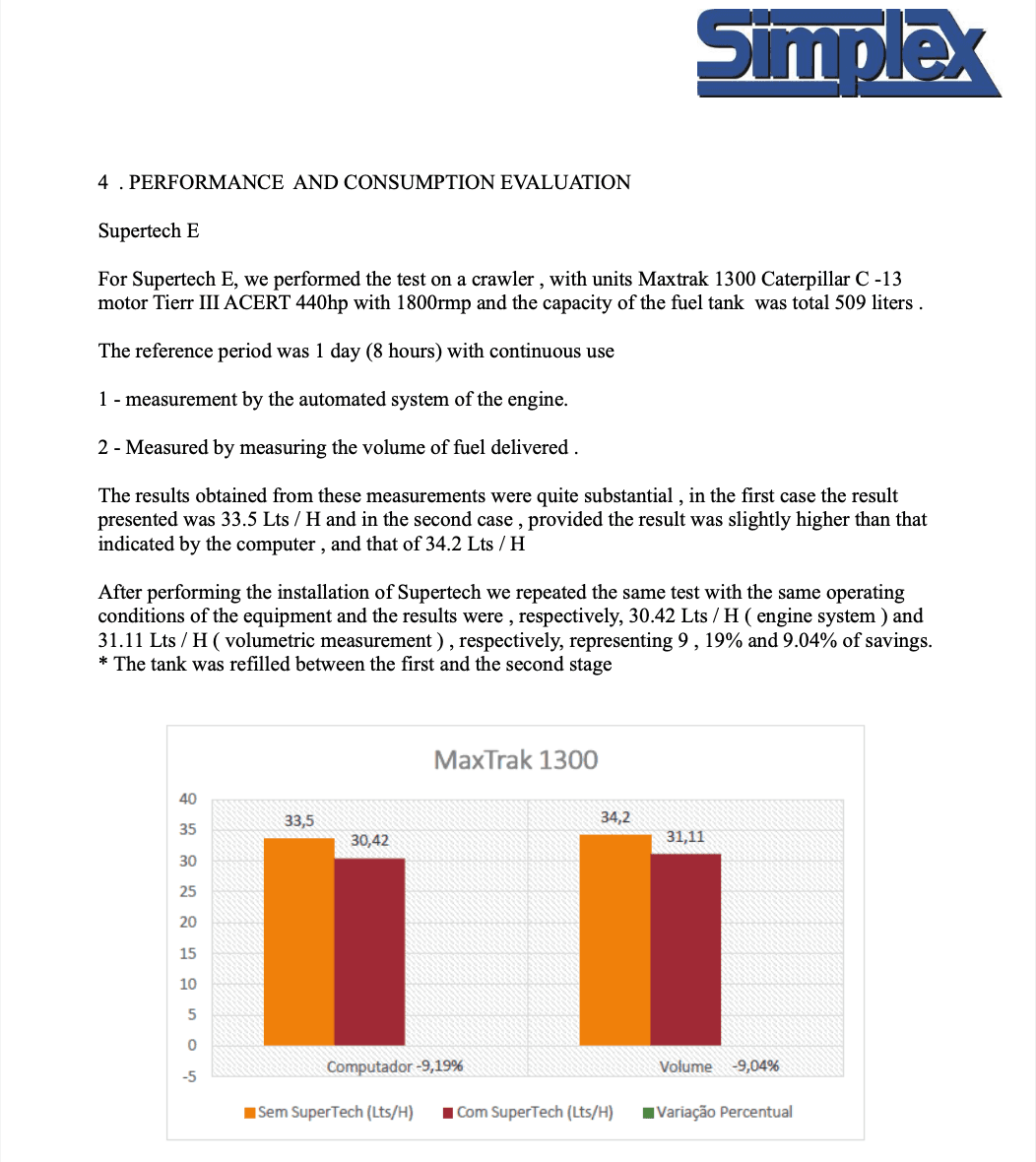

SuperTech® Model E (High-Power Crawler – Diesel)

Equipment: Maxtrak 1300 crawler with Caterpillar C-13 Tier III ACERT engine

Power: 440 HP

Tank capacity: ~509 liters

Test duration:

1 full workday baseline

1 full workday post-installation

Measurement methods:

Engine monitoring system

Volumetric fuel measurement

No engine modifications, tuning, or operational changes were made during the evaluation periods. Fuel tanks were refilled between baseline and post-installation phases to ensure measurement consistency.

What were the observed results following installation?

Across all tested vehicles and equipment, the evaluation documented consistent fuel-consumption reductions following the installation of SuperTech®:

Passenger vehicle (Model B):

Fuel economy improvement of approximately 7.4–7.7%

Crawler crusher (Model D):

Fuel consumption reduction of approximately 8.7–8.8%

High-power crawler (Model E):

Fuel consumption reduction of approximately 9.0–9.2%

When averaged across all tested petrol and diesel platforms, the study reported a mean fuel-savings value of approximately 8.5%.

The evaluation also observed a positive correlation between engine power and fuel-saving magnitude, with higher-output engines demonstrating greater relative improvements.

What is the key takeaway for equipment operators?

This multi-platform field evaluation demonstrates that source-level, in-tank fuel optimization can deliver consistent, repeatable fuel-consumption reductions across a wide range of engine sizes, fuel types, and equipment classes used in aggregate production and mining operations.

Results document observed outcomes under specific operating conditions and do not constitute a regulatory certification or guarantee of results. Performance may vary depending on machine condition, workload, fuel quality, and duty cycle.